Linear Fresnel Reflector (LFR)

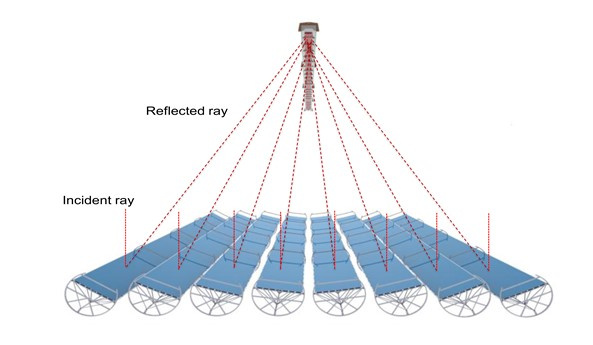

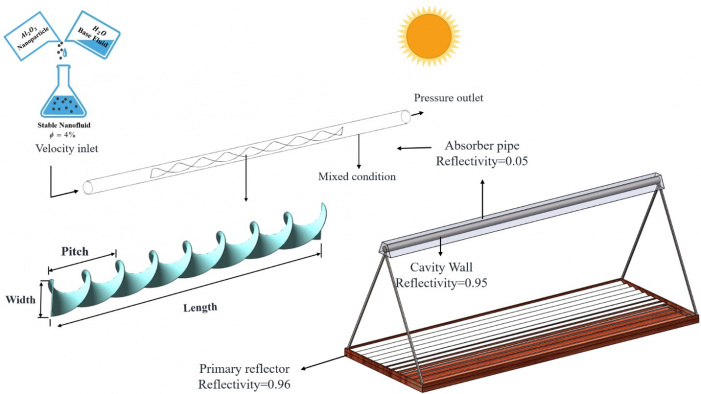

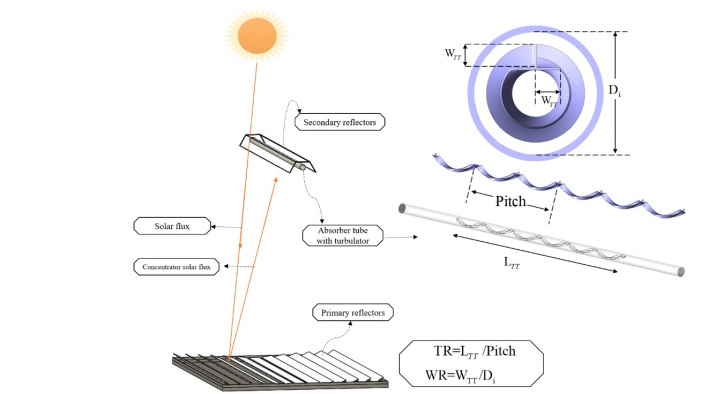

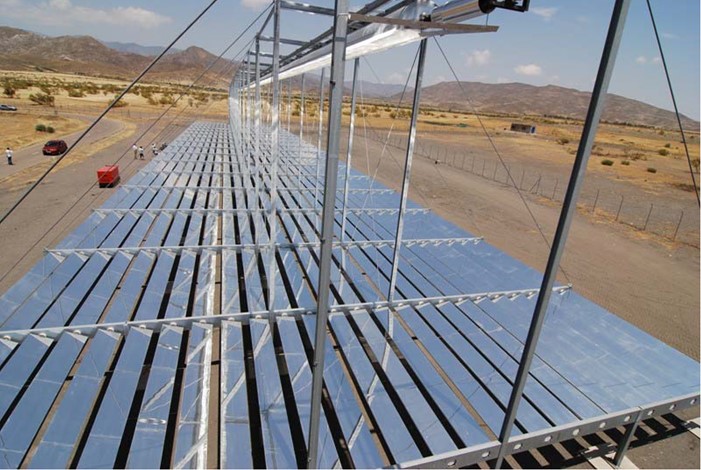

Linear Fresnel Reflector technology relies on an array of linear mirror strips which concentrate light onto a fixed receiver mounted on a linear tower. The receiver is nothing but a stationary linear cavity, usually trapezoidal, consisting of a number of tubes. The inside of the cavity, external to the tubes contains air that is not in contact with the ambient. The tubes are heated by absorbing reflected solar radiation from the LFR field placed at the ground. The water flowing through the tubes inside the cavity absorbs heat and thereby generates steam inside the tubes. The LFR field can be imagined as a broken-up parabolic trough reflector. However, unlike parabolic troughs, the mirrors used for reflection are flat in shape. The greatest advantage of this type of system is that the used flat mirrors cheaper than parabolic glass reflectors. Additionally, these are mounted close to the ground, thus minimizing structural requirements.

Linear Fresnel systems are among the most promising technologies for energy production from concentrated solar radiation. In such plants, a linear fixed receiver is suspended above a solar field composed of strips of mirrors, flat or slightly concentrating; each strip rotates on a fixed horizontal axis in order to reflect the sun radiation towards the receiver.

Linear Fresnel reflector solar concentrator (LFRSC) has several advantages, (i) it is useful for medium-temperature range applications (ii) it is fabricated with narrow flat reflectors and constituent materials for its fabrication as well as a replacement which are readily available in the market; (iii) the planar configuration and the air gap between the adjacent reflectors result in very small wind loading on the concentrator. Because of this, it can be mounted on a rather simple cost-effective supporting structure.